When I moved to Siberia from tropical Guatemala I found out I didn't have any boots. Here in Siberia flip-flops aren't really that useful, there aren't too many hot days in a year.

I went to see what they had in the stores but for me it is always hard to find something I really like, so I decided to make my own. I asked in our local leather community if anyone was teaching shoemaking and found Svetlana Kondratova - a professional leatherworker who has a workshop here in Novosibirsk and makes all kinds of things from reupholstering car interiors to bag and shoe making and tooling.

I scrolled through her posts and saw a pair of very nice leather sneakers made by one of her apprentices. They didn't have a sole attached yet but I was looking for something like this, and I decided to take the masterclass with Sveta.

The whole process took 5 days, working for about 4-6 hours a day, and here is what we did.

MAKING THE BOOTS

First, we had to create the pattern. We took a shoe last that fits my foot by measurements and covered the outside half of it with a masking tape, cutting a clean line at the center afterwards. It was a surprise to me to discover that a shoe pattern is basically symmetrical! Then I drew the shoe design right on that masking tape.

Then this masking tape pattern is taken off the shoe last, flattened on paper and the whole design is transferred to a clean sheet using an awl.

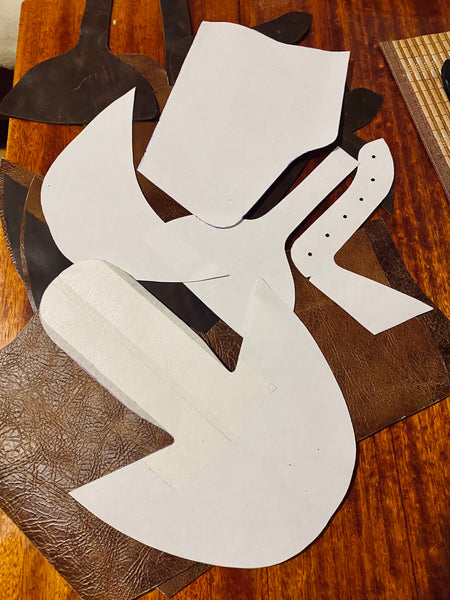

After that, each part of the boot is transferred to different piece of paper and cut out. Using those templates, I cut each part for both boots out of leather of my choice. I chose a nice vintage cowhide that I bought in Guatemala and a darker crazy horse leather for the accents. The leather for the boots should be on the flexible side, in order to be able to shape it around the lasts later.

After cutting everything out, I had to glue the accents onto the main pieces and stitch them together.

The sides were stitched together at the heel and the heel part is stitched on, as well.

We installed the grommets for the laces and glued the central part to the sides before stitching them together.

The whole thing went back onto the lasts and laced up.

Then there was a lot of nails and stinky glue :) The boots had to be shaped around the lasts and securely attached to the insole. This alone took more than one day and then it had to be left to dry overnight.

I forgot to take pictures of the process when this whole mess under the sole was flattened, the excess thickness sliced off, and there was some cork filler glued in the middle to achieve a flat surface.

Then the store bought rubber sole was glued to the boot and pressed down with special device to set properly.

And the last (also forgot to take the pictures) but not least, stitching the sole to the boot with a special awl that has a hook. The sole is stitched on with a "machine style" stitch where one thread is always inside and the other is always outside. No saddle stitch here folks :)

Done!

I must say it was quite a fun and a really amazing experience. I have been making the bags for a while now but with the shoes, it has always been a mystery - how are those made and if I could do it myself.

The hardest part for me was the nail-n-glue part because I was banging all over my fingers with the hammer LOL and the glues are super stinky which for me is quite tough with my sensitive nose.

I am very pleased with the results, and if any of you guys have an opportunity to take a shoemaking class, do it, it is so worth it.

9 comments

I love them! Thank you so much for sharing the process. Do you like the way they fit and feel?

Very interesting! Thank you for sharing it with us!

I am in awe! I have always wanted to make my own shoes, I even recently bought a last for my size + 2 books to guide me into the introductions of making footwear. I have been making bags for a year and a half now but this is my dream. You are so lucky to find a masterclass that taught you how to make your boots, step by step. I am pretty sure that the pride of having done your own boots is exhilarating!

Congratulations on the good work.

I’ve been casually following you via different social media platforms having just started leather working. I too, have branched out to making shoes and I must say, well done! Your shoes look great! I made a similar pair as my second pair of shoes. I know it probably won’t help, as you live in a different country, but where did you get the cup soles for your lasts?